SPC Flooring Extrusion Machine

Romeroca’s SPC Flooring Extrusion Machine is the cornerstone of Stone Plastic Composite (SPC) flooring production. This advanced extruder processes mixed raw materials into a durable SPC core layer using a double-cone screw and T-die, followed by lamination of wear-resistant and decorative films via four- or five-roller calendering to form high-quality SPC flooring boards. As the top-selling extruder in Vietnam and China, manufactured by a leading Chinese factory, it enjoys strong global market popularity due to its efficiency and reliability.

Extrusion Machine Information

Romeroca Extrusion Machine Specifications

| Extruder Model | RFS-Z92/188 | RFS-Z110/220 | RFS-Z92/188 & RFS-Z80/156 For coex |

| Capacity (kg/24h) | 14000-18000 | 25000-28000 | 17000-20000 |

Key Features of Romeroca SPC Flooring Extrusion Line

Patented design with over 10 years of extrusion and lamination expertise.

Energy-efficient, high-output, and stable performance.

Easy embossing roller replacement for flexible production.

User-friendly operation, maintenance, and quality control.

Enhanced peel strength with patented lamination system.

Zero waste during overlay and decor film changes.

Superior shrinkage and bending resistance post-extrusion.

Consistent embossing depth for premium flooring quality.

Customized design for SPC flooring with turnkey project support.

Technical Details of SPC Flooring Extruder Machine

1 | Conical Twin Screw Extruder (110/220) |

| Screw |

|

| Type | Conical Twin Screws |

| Diameter (Front/Back) | 110/220mm |

| Material | 38CrMoAlA with Bimetallic Alloy |

| Treatment | Nitride |

| Thickness of nitride layer | 0.6-0.7mm |

| Hardness | HV 740 – 940 |

| Roughness | Ra≤0.8um |

| Rotation speed(r/min) | 1~34.7 r/min |

| Barrel |

| Barrel material

| 38CrMoAl with SKD Alloy Sleeve |

| Treatment | Nitride with Hardness 900-1000HV |

| Heating zone | Six zones |

| Heating on Feed inlet (1st zone) | Ceramic heater |

| Heater (2nd to 6th zone) | Aluminum heater |

| Heating power(kW) | 80KW |

| Temperature range(℃) | 50~300 |

| Cooling zone | Five zones |

| Cooling | Air blower with Water circulation |

| Drive |

| Motor | AC motor (Siemens Beide/WNM) |

| Motor Power | 200KW |

| Speed driver | Frequency inverter (TECO/ABB) |

| Gearbox | Horizontal |

| Gears material in Gearbox | 20CrMoTi Alloy steel |

| Connection (motor & gearbox) | Motor connected with gearbox in the behind |

| Vacuum venting |

| Vacuum pump | Liquid ring vacuum pump |

| Power | 7.5KW |

| Vacuum degree | 0~-0.09Mpa |

| Dust collection tank | Two pcs |

| Feeding |

| Hopper for loading material | SUS304 stainless steel with sight glass |

| Feeding | By screw rotating |

| Feeding screws | Double screws |

| Drive | 2.2KW gearmotor |

| Speed driver | Frequency inverter (ABB brand) |

| Blender unit | Avoid powder bridging |

| Control |

| Control cabinet | Integrated in the extruder |

| Control cabinet cooling system | Air Blow cooling for power cabinet |

|

Control | All motors and temperature control circuits (total 16 zones) and melt pressure and alarms in extruder |

| Temperature Control type | Temperature control meters |

| Manu display in language | English / Chinese |

| Operation | Touch and button |

| Overload alarm | Included |

| General parameter |

| Extruder Max. capacity | 1500kg/h |

| Production capacity (recommend) | 1000-1250kg/h |

| 4 mm product | 3000-3500 m²/day |

| Total installation power | 300KW |

| Weight | 11500Kg |

| Length | 8000mm |

| Width | 1800mm |

| Height (included loader) | 4800mm |

| Extrusion centerline height | 1000mm |

|

2 | T-Die |

| Outlet width | 1050mmm (to be confirmed when place order) |

| Outlet gap for thickness | 3-6mm |

| Max width of product | 980-1000mm |

| Thickness range for product | 3-6mm |

| Structure | Coat hanger type |

| Material | 5CrNiMo mould alloy steel |

| Die lip flow surface roughness | 0.015-0.02 um |

| Chrome plate in the flow channel | 0.04-0.06 mm |

| Heating | Electrical heater |

| Heating zone | 7 zones |

| Fasten | By bolts |

| Total installation power | 36KW |

| Weight | 1000Kg |

|

3 | Support Frame for T-die |

| Material | Steel frame with painting |

| Moving | On rail |

| Centerline height | 1000mm |

| Height adjustment range | 50mm |

| Weight | 100Kg |

|

4 | Four Roller/Five Roller Calender with lamination |

| Roll quantity | Four rollers / Five Rollers |

| Structure | L type with rollers horizontal layout |

| Body of Frame | Square Steel frame |

| Roller diameter | 400mm |

| Roller length | 1500mm |

| Roller raw material | Seamless steel tube |

| Treatment on roller | Quench and surface chrome plate |

| Hardness on roller surface | >HRC50 |

| Chrome plate thickness | 0.08-0.12mm |

| First 1 and 2 rollers | Mirror roller |

| Mirror roller surface | Ra<0.025um |

| 3rd roller for sheet bottom surface | Embossed as Seller standard |

| 4th roller for sheet top surface | Pattern as buyer ordered |

| Surface embossing depth monitor | Included |

| Roller rotating driven | Gear motor |

| Motor | 1.5KW x 4 sets/ 5 sets |

| Motor quantity

| 4 sets /5 sets independent drive on each roller |

| Rotating speed control | Frequency inverter from ABB |

| Linear Speed | 0-6m/min |

| Speed synchronization on all rollers | Included |

| Distance between rollers | 0-50mm |

| Distance adjustment | By motor or manual |

| Roller move driven | 0.37KW x 2 sets for 1st and 4th roller/ 5th Roller |

| Bearing | For high temp. resistance |

| Rotating connectors | 8 pcs of 1.25’’ inch |

| Calender moving | On guide rail |

| Movement motor | 1.5KW AC motor |

| Control | Meter control |

| Total installation power | 10KW |

| Weight | 9500Kg |

|

5 | Lamination device |

| Platform height | 2400mm |

| Unwinder shaft | Four pcs |

| Air Shaft diameter | 76mm |

| Shaft length | 1500mm |

| Tension control | Magnetic powder brake |

| Film feeding device | Two sets |

| Haul off for film | Steel roller and rubber roller |

| Feeding device driven | 0.55Kw |

| Deviation rectification control | Included |

| Unwinder Movement | on linear guideway |

| Lamination press roller | Two sets of 120mm Silicon rubber rollers |

| Total installation power | 10 KW |

| Weight | 1200 Kg |

|

6 | Roller temperature controller |

| Controller quantity | Each set for each roller |

| Conduct media | Conduct oil |

| Cooling media | Soft water (from factory water circulation) |

| Temp control range | 40-200℃ |

| Temp control tolerance | +1℃ |

| Oil pump power | 2.2KW x 3 sets |

| Heating power | 15KW x 3 sets |

| Total installation power | 50KW |

| Weight | 500Kg |

|

7 | Cooling bracket |

| Length | 16m |

| Width | 1500mm |

| Roller | Stainless steel roller |

| Air curtain blower for cooling | 4 sets + 2 sets Air Blower |

| Total installation power | 1.5KW |

| Weight | 700 Kg |

|

8 | Trimming blade |

| Blade quantity | Two pieces |

| Trimming width on product | As per T-die width |

| Weight | 20 kg |

9 | Haul off |

| Type | Rollers pulling |

| Rollers quantity | one couples |

| Roller size | 1500mm |

| Roller diameter | 250mm |

| Roller | Rubber roller |

| Clamp | Pneumatic cylinder |

| Drive | 3KW gear-motor |

| Transmission | Gears drive |

| Speed control | Frequency inverter (ABB brand) |

| Speed range | 0-4m/min |

| Total installation power | 3 6W |

| Weight | 1000 Kg |

|

10 | Shear cutter |

| Cutting | Guillotine cutting |

| Cutting Max width | 1300mm |

| Cutting Max thickness | 1-6mm |

| Cutting motor | Brake motor |

| Total installation power | 5.5KW |

| Weight | 800 Kg |

|

11 | Auto Stacker |

| Length counting | Position sensor |

| Suction cup | 8 pcs |

| Lifting weight | Up to 50kg |

| Size of estimated product | 1000mm x 1800mm |

| Moving drive | Servo motor |

| Control and parameter input | PLC |

| Installation power | 4KW |

| Weight | 550kg |

| Components brand list |

A. | Main Motor of Mixer and Extruder | Siemens standard /WNM |

B. | Frequency inverter of extrusion line | ABB/TECO |

C. | Temperature meter | RKC/Omron/FIJI |

D. | Electrical components | Siemens / Schneider / CHINT / DELIXI |

E. | Gearmotor | REDSUN |

F. | T-die | Top brand |

Romeroca Electrical Partners

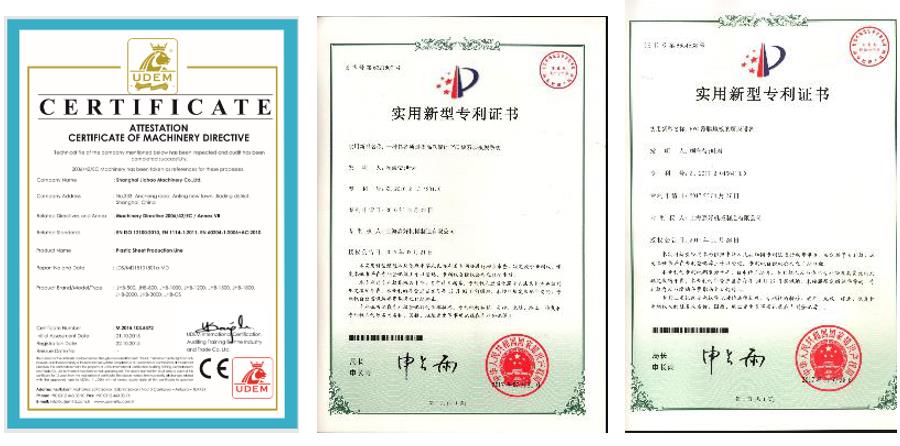

Romeroca Certificates and Patents

Overseas Cases of Extrusion Machine

What is SPC Flooring?

SPC (Stone Plastic Composite) flooring is an advanced form of luxury vinyl tiles (LVT), composed of natural limestone powder, polyvinyl chloride (PVC), and stabilizers in a specific ratio, creating a highly stable composite material. Known for its exceptional stability, waterproof properties, high-density solid core, and indentation resistance, SPC flooring is ideal for both residential and commercial spaces. It is formaldehyde-free, ensuring safety, and can be installed over various floor bases like concrete, ceramic, or existing flooring. The SPC core typically consists of 60% calcium carbonate, 20% PVC, and 20% plasticizers, with layers including UV coating, wear-resistant layer, PVC decor film, SPC core, and EVA/IXPE underlay.

Full Production Processes of SPC Flooring

1. Crushing & Milling

SPC production generates fragment waste, which is crushed and milled into powder for recycling into raw materials, a key component in the SPC material ratio.

2. Mixing

Raw materials are uniformly mixed in a high-speed mixer to remove moisture, then cooled in a cold mixer to prevent agglomeration and discoloration.

3. Extrusion

Mixed materials are extruded into a sheet using a twin-cone screw and T-die, with wear-resistant and color films laminated via four- or five-roller calendering to form SPC boards.

4. UV Coating

A UV coating machine applies a protective layer to enhance dust resistance, scratch resistance, abrasion resistance, and uniform gloss.

5. Cutting

An automatic multiple ripsaw cuts large SPC boards into planks of required sizes.

6. Slotting

A longitudinal and transverse double-end tenoner processes the plank edges into specific lock shapes using suitable click systems and PCD cutters.

7. V-Groove Painting

Optional V-groove painting enhances the aesthetic appeal of SPC flooring edges, similar to laminate flooring, based on market preferences.

8. IXPE/EVA Underlay Laminating

Hot melt adhesive bonds IXPE or EVA underlay to the SPC flooring back, improving sound insulation and comfort for high-end products.

9. Packing

Fully or semi-automatic packing machines are available to meet varying automation needs.

About Romeroca

With 16 years of expertise in the flooring industry and over 10 years in the Asian market, Romeroca is a trusted provider of one-stop supply and services for global flooring factories. Our state-of-the-art SPC flooring extrusion machines, raw materials, and technical services empower manufacturers to achieve superior production outcomes. Request a Quote to explore how Romeroca can elevate your flooring production.

What We Offer for SPC Flooring Projects

1. SPC Flooring Full Production Line

Comprehensive equipment including SPC flooring extruder, mixer, crushing & milling machine, UV coating machine, click slotting machine, cutting machine, V-groove painting machine, IXPE/EVA lamination machine, and packing machine.

2. Raw Materials for Rigid Core PVC Flooring

Chemicals: PVC SG5, stabilizer, ACR, CPE, PVC lubricant, PE wax. Additional materials: wear-resistant layer, PVC decor film, IXPE/EVA underlayment, UV paint. Romeroca has supplied 20 million meters of PVC decor film globally and can bundle materials to reduce shipping costs.

3. Spare Parts for SPC Flooring Manufacturing

PCD cutters, PCD saw blades, extruder mould, surface rollers, screw & barrel, UV rollers, UV lamps, and all necessary accessories for SPC flooring production.

4. Test Equipment for SPC Flooring Factories

Drying ovens, tensile testers, wear testers, scratch testers, click strength testers, click projectors, and other essential testing equipment for quality control.

Our Services & After-Sales Support

12-month warranty on all Romeroca machines (excluding wear parts).

36-month tracking service with 24-hour response time.

Factory production process and machine layout design.

Technical guidance, training, and support.

Timely supply of spare parts.

Comprehensive support from raw materials to finished products.

Frequently Asked Questions

What is an SPC Flooring Extrusion Machine?

An SPC Flooring Extrusion Machine produces Stone Plastic Composite (SPC) flooring by extruding raw materials into a core layer and laminating wear-resistant and decorative films, ideal for durable, waterproof flooring.

How does SPC flooring compare to LVT or WPC?

SPC flooring offers enhanced rigidity and stability over LVT and WPC due to its stone-plastic core, making it perfect for high-traffic environments.

What is the production capacity of Romeroca’s SPC extruder?

Depending on the model, Romeroca’s SPC extruders deliver capacities of 14,000-28,000 kg per 24 hours, ensuring efficient large-scale production.

Can the machine produce varying SPC flooring thicknesses?

Yes, the machine supports SPC flooring thicknesses from 3 to 6 mm, customizable to meet diverse market requirements.

Is Romeroca’s extruder suitable for small-scale factories?

Romeroca’s extrusion machines are designed with flexible configurations, making them ideal for both small-scale and large-scale SPC flooring production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Aymara

Azərbaycan dili

Беларуская мова

Corsu

guarani

Chichewa

Runasimi

Sesotho