Laminate Flooring Saw Cutting Machine for Precision Cutting

Romeroca’s Laminate Flooring Saw Cutting Machine (Models: RFS-2500, RFS-1300) is designed to automatically cut large laminate flooring boards into precise planks. Utilizing advanced technology, this machine ensures high efficiency, quick switching, and support for various product specifications. It delivers straight cuts with no chipping, high precision, and flat edges, saving labor and material costs while boosting production capacity.

Saw Cutting Machine Specifications and Features

| Parameter | RFS-2500 | RFS-1300 |

| Power of Main Motor | 3 kW × 4 | 18.5 kW |

| Motor of Material Feeding | 1.5 kW | 1.5 kW |

| Maximum Revolution | 2980 r/min | 3200 r/min |

| Specification of Saw Disc | 300×3.2×2.2×40 mm | 300×3.2×2.2×(80–100) mm |

| Thickness of Workpiece | 3–25 mm | 3–20 mm |

| Speed of Sawing | 15–35 m/min | 15–35 m/min |

| Linearity of Board | <0.2 mm/m | <0.2 mm/m |

| Diameter of Saw Piece Shaft | Φ80 mm | Φ80–Φ100 mm |

| Overall Dimensions (L×W×H) | 1250×3250×1200 mm | 1600×2200×1200 mm |

| Machine Weight | 2.1 T | 2.6 T |

Key Features of Romeroca Laminate Flooring Saw Cutting Machine

- Saves labor and material costs with automated cutting processes.

- Boosts production capacity with high-speed operation (15–35 m/min).

- Delivers precise, straight cuts with no chipping and flat edges (linearity <0.2 mm/m).

- Easy operation via PLC computer control system for efficient management.

- Elegant, rust-resistant design meeting European and U.S. standards.

- Advanced automatic control software for production information management.

- High-precision anti-collision laser cutting head ensures optimal cutting results.

Romeroca Electrical Partners for Cutting Systems

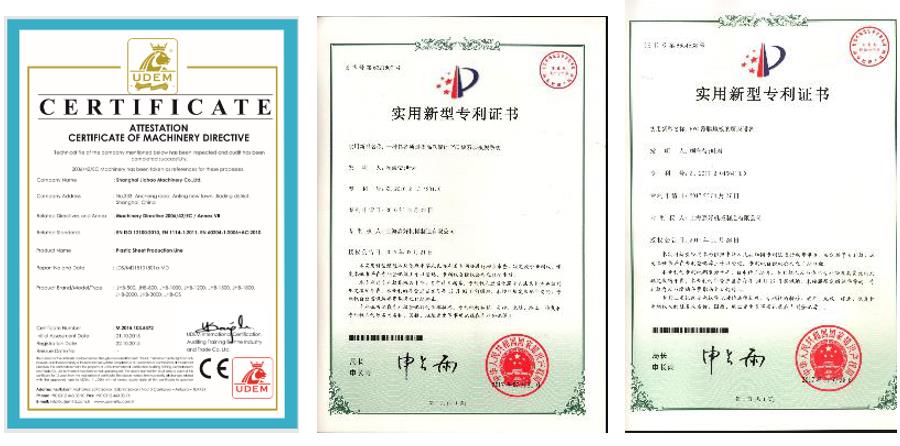

Romeroca Certificates and Patents for Cutting Technology

Laminate Flooring Saw Cutting Machine Project Cases

What is Laminate Flooring?

Laminate flooring is composed of four layers: balance paper, high-density fiberboard (HDF), decorative paper, and overlay paper. It is created by crushing logs, adding preservatives and additives, and pressing them under high temperature and pressure using a hot press machine. This process enhances stability, overcoming the weaknesses of natural wood. With a click system for easy installation and removal, laminate flooring is affordable, offers diverse designs and colors, and provides excellent wear resistance, easy maintenance, and convenient installation.

Full Production Process of Laminate Flooring with Precision Cutting

1. Boiler

A boiler supplies heat to the hot press machine using thermal oil, with fuel options including coal, natural gas, diesel, or electricity.

2. Hot Pressing

The hot press machine (typically 4ft×8ft, 2800T) presses exquisite patterns onto HDF boards using stainless steel chroming plates, ensuring a tight bond with decorative and overlay papers.

3. Cooling Platform

A cooling platform rapidly cools flooring pressed at 200°C, stabilizing dimensions and ensuring tight adhesion of layers.

4. Cutting

Romeroca’s saw cutting machine (RFS-2500, RFS-1300) cuts large laminate boards into precise planks, ensuring straight cuts and high precision.

5. Slotting

A longitudinal and transverse double-end tenoner processes plank edges into specific lock shapes using suitable click systems and PCD cutters.

6. Dust Collection

A dust collection system removes heavy dust generated during cutting and slotting, ensuring a cleaner flooring product and work environment.

7. V-Groove Painting

Optional V-groove painting enhances the aesthetic appeal of laminate flooring edges, making them visually appealing to customers.

8. Wax Coating

A wax coating machine applies paraffin wax, providing waterproofing, moisture resistance, anti-aging, formaldehyde prevention, and lubrication for enhanced durability.

9. Packing

Fully or semi-automatic packing machines are available to meet varying automation needs.

About Romeroca Flooring Solutions

With 16 years of expertise in the flooring industry and over a decade in the Asian market, Romeroca is a trusted provider of one-stop solutions for global flooring factories. Our advanced laminate flooring production lines, including saw cutting machines, raw materials, and technical services, empower manufacturers to achieve superior outcomes. Request a Quote to explore how Romeroca can elevate your flooring production.

What We Offer for Laminate Flooring Projects

1. Complete Laminate Flooring Production Line

Comprehensive equipment including hot press machine, cooling line, cutting machine, click slotting machine, dust collection machine, V-groove painting machine, wax coating machine, and packing machine.

2. Raw Materials for Laminate Flooring

Overlay/wear layer paper, decorative paper, balance paper, and melamine paper (post-impregnation). Romeroca can bundle materials to reduce shipping costs.

3. Spare Parts for Laminate Flooring Manufacturing

PCD cutters, PCD saw blades, cushion pads (silicon & copper), chroming plates, and all necessary accessories for laminate flooring production.

4. Testing Equipment for Laminate Flooring Factories

Wear testers, click strength testers, click projectors, and other essential testing equipment for quality control.

Our Services and After-Sales Support for Cutting Systems

- 12-month warranty on all Romeroca machines (excluding wear parts).

- 36-month tracking service with 24-hour response time.

- Factory production process and machine layout design.

- Technical guidance, training, and support.

- Timely supply of spare parts.

- Comprehensive support from raw materials to finished products.

Frequently Asked Questions About Saw Cutting Machines

What is a Laminate Flooring Saw Cutting Machine?

A laminate flooring saw cutting machine, like Romeroca’s RFS-2500 and RFS-1300, automatically cuts large laminate boards into precise planks, ensuring high efficiency and accuracy.

What are the benefits of Romeroca’s saw cutting machine?

It offers labor and cost savings, high-speed production (15–35 m/min), precise straight cuts with no chipping, and flat edges with high linearity (<0.2 mm/m).

What flooring thicknesses can the machine handle?

The machine supports workpiece thicknesses of 3–25 mm (RFS-2500) and 3–20 mm (RFS-1300), accommodating a wide range of laminate flooring.

How does the machine ensure precision cutting?

It uses a high-precision anti-collision laser cutting head, PLC control system, and advanced saw discs to ensure straight, chip-free cuts with flat edges.

What control system does the machine use?

The machine is equipped with a PLC computer control system for easy operation and efficient production management.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Shqip

বাংলা

Hrvatski

Afrikaans

Eesti keel

Aymara

Azərbaycan dili

Беларуская мова

Corsu

guarani

Chichewa

Runasimi

Sesotho